Manufacturing

Smarter Decisions, Less Effort:

Automate Supplier Evaluation Using AI

Streamline Supplier Evaluation for Effective Procurement Decisions With ZBrain Flow

Problem

The Data Complexities of Supplier Evaluation

Selecting the right supplier is a pivotal decision that can make or break a business’s success. However, the task of choosing the optimal supplier is burdened with numerous factors to consider and overwhelming volumes of data to analyze, making it a time-consuming process. ZBrain Flow helps you tackle this challenge by simplifying supplier evaluation and selection processes.

Solution

I. How ZBrain Flow Streamlines the Supplier Evaluation Process

Utilizing artificial intelligence and machine learning capabilities, ZBrain automates the traditionally manual supplier evaluation process. Here’s a comparison of the time required for each task with and without ZBrain Flow:

|

Steps |

Without ZBrain Flow |

Time Without ZBrain Flow |

With ZBrain Flow |

|---|---|---|---|

| Data acquisition | Manual | ~8 hours | Automated by ZBrain Flow |

| Data cleaning and preparation | Manual | ~6 hours | Automated by ZBrain Flow |

| Data analysis | Manual | ~8 hours | Automated by ZBrain Flow |

| Report generation | Manual | ~6 hours | Automated by ZBrain Flow |

| Report review and finalization | Manual | ~2 hours | Manual |

| Total | ~30 hours | ~3 hours |

As evident from the table, ZBrain Flow significantly reduces the time spent on the supplier evaluation process from approximately 30 hours to just around 3 hours, yielding substantial time and cost savings.

II. Necessary Input Data

For ZBrain Flow to operate optimally and generate accurate output, it requires the following data:

|

Information Source |

Description |

Recency |

|---|---|---|

| Company’s Internal ERP/CRM System | Internal records of supplier history, performance, and contracts | Always Updated |

| Public Financial Statements from SEDAR, EDGAR | Publicly available financial reports | Last Fiscal Year |

| Compliance information from FDA, EPA Database | Records of supplier compliance/non-compliance with regulations | Last 1 Year |

| RFP Responses | Supplier proposals in response to the issued RFP | Current Cycle |

| Regulatory information from SEC, SEDAR | Information on legal issues or penalties faced by suppliers | Last 1 Year |

| Credit Rating from Dun & Bradstreet | Credit reports or ratings of supplier’s financial health | Last Fiscal Year |

III. ZBrain Flow: How It Works

Step 1: Data Acquisition and Exploratory Data Analysis (EDA):

The initial stage of an effective supplier evaluation process involves data collection, a critical step seamlessly handled by ZBrain Flow. ZBrain automatically pulls relevant data such as supplier profiles, proposals, historical performance, compliance records, financial statements, and credit ratings from various sources.

Once the data is gathered, ZBrain initiates an automated Exploratory Data Analysis (EDA) to unveil valuable insights. EDA involves understanding the structure of the data and identifying missing values, outliers, correlations, and patterns that can influence supplier evaluation.

Step 2: Embedding Generation:

In this step, the textual data (supplier profiles, proposals, compliance records) is transformed into numerical representations using embedding techniques, such as word embeddings or sentence embeddings. These embeddings capture the semantic meaning and relationships between different data points, facilitating efficient retrieval and analysis. This seamless transformation enables ZBrain to deliver insights with remarkable precision and empowers your decision-making process with a wealth of knowledge at your disposal.

Step 3: Query Execution and Report Generation:

Whenever a user submits a query for the supplier evaluation report, the relevant data gets fetched based on the query requirements. This fetched data and the query are then passed on to the OpenAI Language Model (LLM) for report generation.

Leveraging the acquired embeddings, the OpenAI LLM comprehends and contextualizes the data, delving into the depths of information provided. Drawing from the dataset, query details, and the report’s intended structure, the OpenAI LLM dynamically generates a comprehensive and coherent report text.

Step 4: Parsing the Generated Report:

Once the supplier evaluation report is generated in text format, a meticulous parsing process is initiated, expertly extracting essential information like supplier evaluations, scores, rankings, and conclusions. This parsed data is then thoughtfully structured, ensuring the final report adheres precisely to the desired format, sections, and report guidelines.

ZBrain seamlessly incorporates the necessary headers, formatting, and references to create a comprehensive and coherent supplier evaluation report. This meticulous approach ensures that the report is not only data-driven but also presented in a professional and easily digestible manner.

By harmoniously integrating data acquisition, automated EDA, embedding generation, query execution with LLM, report generation, and parsing, ZBrain masterfully produces the final version of the supplier evaluation report. This multifaceted process empowers you with valuable insights and equips you to make strategic and well-informed decisions for your organization.

Impact

Streamlined Supplier Selection and Evaluation

With an automated, AI-powered process, ZBrain dramatically reduces the time and effort required for supplier evaluation. Evidently, the traditional evaluation process that typically took approximately 30 hours is now streamlined to just around 3 hours, yielding notable time and cost savings. Procurement managers can now assess suppliers more quickly and accurately, paving the way for better business decisions and a fortified supply chain. Embrace the power of ZBrain Flow to unlock unparalleled efficiency and maximize your organization’s success.

Example Report

Prompt:

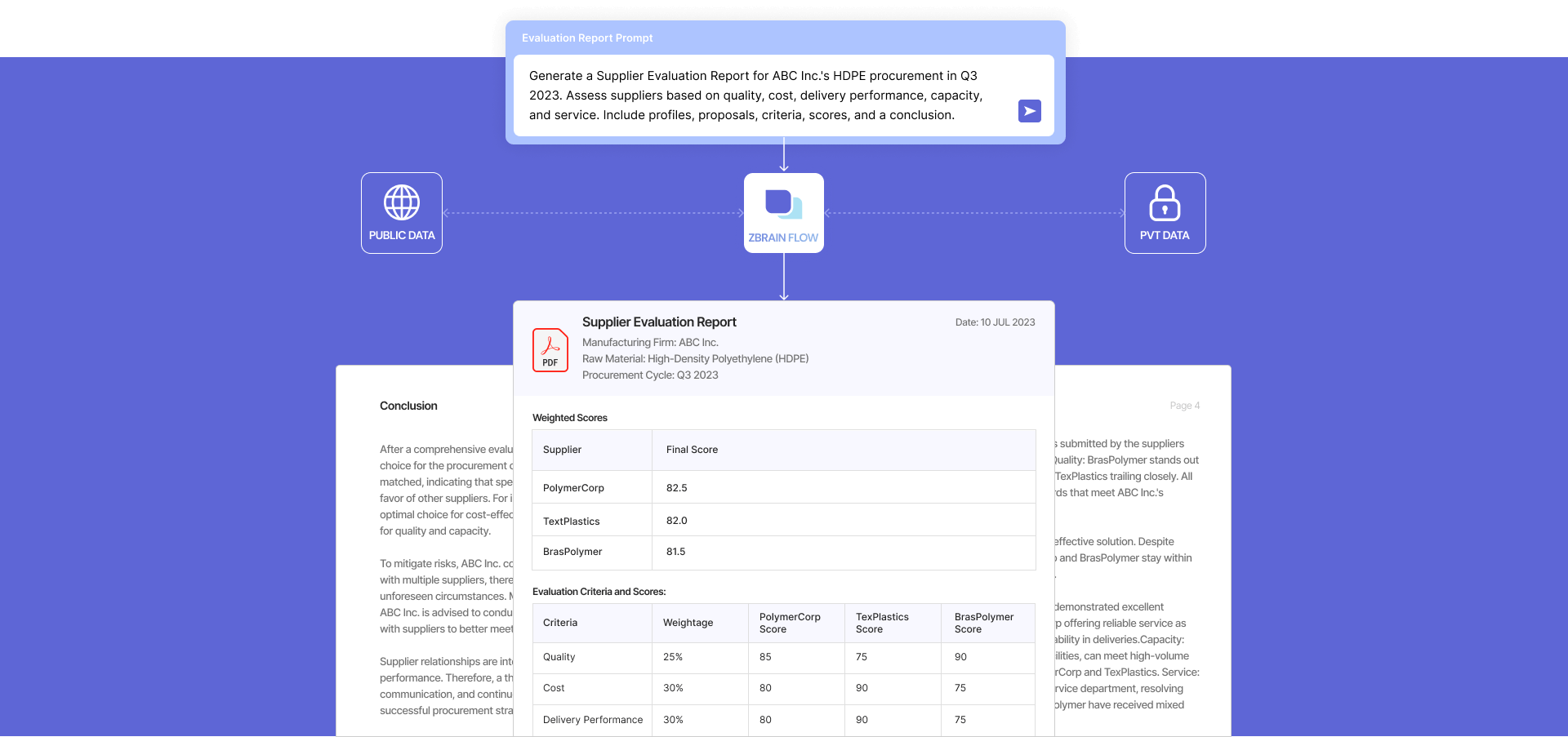

Generate a Supplier Evaluation Report for ABC Inc.’s HDPE procurement in Q3 2023. Assess suppliers based on quality, cost, delivery performance, capacity, and service. Include profiles, proposals, criteria, scores, and a conclusion.

Supplier Evaluation Report for ABC Inc.’s HDPE Procurement in Q3 2023

Introduction:

This extensive report is purposed to evaluate potential suppliers for the procurement of High-Density Polyethylene (HDPE) for ABC Inc.’s Q3 2023 cycle. HDPE, a crucial material in our production of plastic bottles, corrosion-resistant piping, geomembranes, and plastic lumber, has been sourced from suppliers demonstrating key strengths in terms of quality, cost, delivery performance, capacity, and service. The evaluation has been further enriched with the integration of publicly available data about these suppliers, taking into account third-party reviews, financial health, and compliance records, among other aspects.

Request For Proposal (RFP):

The RFP was issued to invite potential suppliers to submit their proposals for supplying HDPE. The RFP outlined the following:

- ABC Inc.’s specific requirements concerning the quality, quantity, and delivery timeline for HDPE.

- The terms and conditions for engagement.

- Key performance indicators that would be used in evaluating the suppliers.

The RFP also required suppliers to provide detailed information about their operations, compliance records, financial stability, and any other factors that would contribute to their overall evaluation. The goal was to ensure ABC Inc. had comprehensive knowledge about the suppliers’ capabilities and reliability before entering into a contractual agreement.

Supplier Profiles and Proposals:

- PolymerCorp Ltd.

Public Information:

PolymerCorp, a public entity (TSX: PLC) in Ontario, Canada, has a strong financial foundation coupled with a consistent growth record. Having been in business for 15 years, it has a proven track record in compliance, particularly with environmental regulations.

Proposal Highlights:

PolymerCorp’s proposal outlines its commitment to providing consistent quality and top-notch customer service. They propose a competitive rate of $X per unit of HDPE, with a standard delivery timeline of Y days. They have also expressed a willingness to expedite orders for an additional cost if necessary.

- TexPlastics Inc.

Public Information:

TexPlastics Inc., a privately-owned firm based in Texas, USA, has been in operation for a decade. They have demonstrated steady growth, as indicated by Dun & Bradstreet data. They maintain a clean compliance record, although there have been some minor issues with delivery timelines in the past.

Proposal Highlights:

TexPlastics’ proposal primarily focuses on cost-effectiveness, proposing a unit cost of $X, the lowest among all the suppliers. They have also specified a longer standard delivery timeline of Y days, attributable to their smaller operation size.

- BrasPolymer S.A.

Public Information:

Based in Sao Paulo, Brazil, BrasPolymer has a solid 20-year presence in the industry. They are publicly listed (BOVESPA: BPOL), displaying robust financial health. However, they have faced criticism over minor lapses in environmental compliance as per public records.

Proposal Highlights:

BrasPolymer’s proposal details their provision of top-quality HDPE at a higher unit cost of $X. They assure a consistent supply and also offer a flexible delivery schedule, with Y days as their standard delivery timeline.

Evaluation Criteria and Scores:

|

Criteria |

Weightage |

PolymerCorp Score |

TexPlastics Score |

BrasPolymer Score |

|---|---|---|---|---|

| Quality | 25% | 85 | 75 | 90 |

| Cost | 30% | 80 | 90 | 75 |

| Delivery Performance | 20% | 75 | 85 | 80 |

| Capacity | 15% | 80 | 70 | 85 |

| Service | 10% | 90 | 80 | 75 |

Note: Scores are based on a scale of 100, with 100 representing the best possible score.

Detailed Analysis:

The analysis was founded on the proposals submitted by the suppliers and their historical performance data.

Quality: BrasPolymer stands out in HDPE quality, with PolymerCorp and TexPlastics trailing closely. All three suppliers maintain quality standards that meet ABC Inc.’s requirements.

Cost: TexPlastics offers the most cost-effective solution. Despite having a higher cost, both PolymerCorp and BrasPolymer stay within the industry-standard cost parameters.

Delivery Performance: TexPlastics has demonstrated excellent delivery performance, with PolymerCorp offering reliable service as well. BrasPolymer also shows good reliability in deliveries.

Capacity: BrasPolymer, with larger production facilities, can meet high-volume demands more effectively than PolymerCorp and TexPlastics.

Service: PolymerCorp excels in the customer service department, resolving issues promptly. TexPlastics and BrasPolymer have received mixed service reviews.

Weighted Scores:

Upon taking into account the weights assigned to each criterion, the following final scores emerge.

|

Supplier |

Final Score |

|---|---|

| PolymerCorp | 82.5 |

| TexPlastics | 82.0 |

| BrasPolymer | 81.5 |

Conclusion:

After a comprehensive evaluation, PolymerCorp emerged as the top choice for the procurement of HDPE. However, the scores are closely matched, indicating that specific priorities could sway the decision in favor of other suppliers. For instance, TexPlastics could be the optimal choice for cost-effectiveness, while BrasPolymer stands out for quality and capacity.

To mitigate risks, ABC Inc. could consider maintaining relationships with multiple suppliers, thereby ensuring a backup plan in case of any unforeseen circumstances. Moreover, this report is an initial guide. ABC Inc. is advised to conduct further due diligence and negotiate with suppliers to meet the company’s specific requirements better.

Supplier relationships are integral to a company’s overall performance. Therefore, a thorough analysis, transparent communication, and continuous supplier evaluation are critical to a successful procurement strategy.