Transforming Consumer Electronics With AI-driven Supply Chain Optimization

Problem

The Data Intricacies in Supply Chain Optimization

In the consumer electronics industry, supply chain optimization is crucial for maintaining efficiency and competitiveness. However, it presents a complex challenge due to the sheer volume of data generated across various stages, from component sourcing to distribution. Traditional methods struggle to manage and derive actionable insights from this vast data pool. Dealing with fragmented data, ensuring its quality and consistency, accessing real-time insights, and conducting effective analysis amplify the complexity. ZBrain addresses these challenges by simplifying supply chain optimization and demand forecasting processes. With streamlined solutions, ZBrain enhances efficiency and decision-making capabilities within the consumer electronics industry.

Solution

I. How ZBrain Streamlines Supply Chain Optimization Process

Leveraging sophisticated artificial intelligence and machine learning capabilities, ZBrain automates and optimizes traditionally manual supply chain processes. Here’s a comparison of the time required for each task with and without ZBrain:

|

Steps

|

Without ZBrain Flow

|

Time Without ZBrain Flow

|

With ZBrain Flow

|

|---|---|---|---|

| Data collection | Manual | ~8 hours | Automated |

| Data cleaning and preparation | Manual | ~6 hours | Automated |

| Data analysis | Manual | ~10 hours | Automated |

| Report generation | Manual | ~6 hours | Automated |

| Report review and finalization | Manual | ~2 hours | Manual |

| Total Time | ~32 hours | ~3 hours |

II. Necessary Input Data

For optimal performance and accurate output, ZBrain relies on the following essential data:

| Information Source | Description | Recency |

|---|---|---|

| Internal ERP/CRM system | Internal records of inventory, production schedules, and customer orders. | Always updated |

| External market data | Market trends, consumer preferences, and industry forecasts. | Current |

| Supplier data | Historical data on supplier profiles, performance history, lead times, reliability, pricing, quality, and compliance records of suppliers. | Regularly updated |

| Transportation and logistics data | Shipping schedules, routes, carrier rates, transit times, and delivery statuses. | Real-time updates |

| Inventory management system | Inventory levels, stockouts, and replenishment schedules. | Real-time updates |

| Quality control reports | Inspection results, defect rates, and corrective actions. | Regularly updated |

| Regulatory compliance records | Certifications, standards, and compliance history. | Last 1 Year |

| Customer order data | Real-time information on order volumes, patterns, and preferences. | Recently updated |

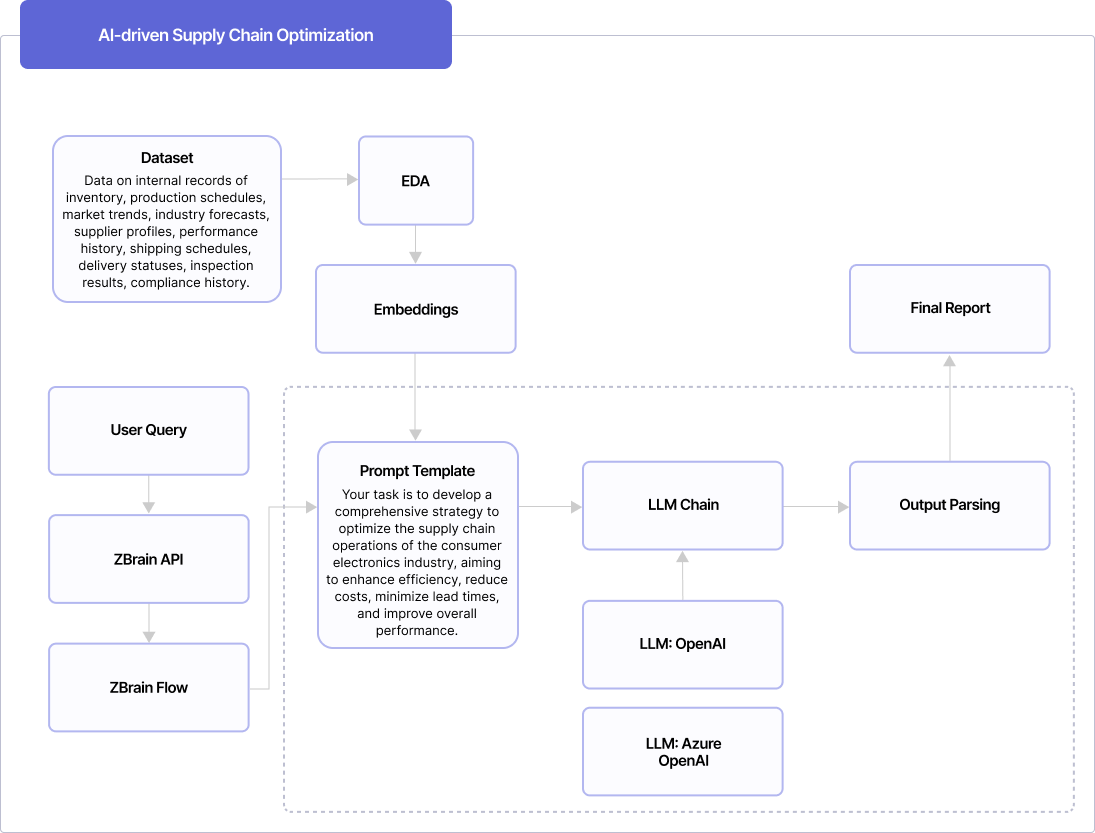

III. How Does ZBrain Work?

Step 1: Data Acquisition and Exploratory Data Analysis (EDA)

The initial stage of effective supply chain optimization involves comprehensive data collection, seamlessly managed by ZBrain. ZBrain automatically retrieves relevant data such as sales forecasts, inventory levels, supplier performance metrics, transportation data, and historical records from various sources.

Once the data is collected, ZBrain automatically conducts Exploratory Data Analysis to uncover beneficial insights. EDA entails understanding the data structure and identifying missing values, outliers, correlations, and patterns essential for optimizing the supply chain.

Step 2: Embedding Generation

In this phase, textual data related to supply chain operations, such as sales forecasts, inventory reports, and transportation schedules, undergo transformation into numerical representations using embedding techniques like word embeddings or sentence embeddings. These embeddings capture semantic meaning and relationships, facilitating efficient retrieval and analysis, thereby empowering decision-making processes with actionable insights.

Step 3: Query Execution and Report Generation

When a user queries the ZBrain app regarding supply chain optimization, relevant data is fetched based on query requirements. This data and the query are fed into the OpenAI Large Language Model (LLM) for report generation.

Leveraging the acquired embeddings, the OpenAI LLM comprehends and contextualizes the data, generating a comprehensive report tailored to the query requirements. Drawing from the dataset, query details, and desired report structure, the OpenAI LLM dynamically produces coherent and implementable insights.

Step 4: Parsing the Generated Report

Once the optimization report is generated, a meticulous parsing process begins, expertly extracting essential information such as optimization strategies, performance metrics, and recommendations. This parsed data is then structured meticulously to ensure adherence to the desired format and guidelines.

ZBrain seamlessly incorporates necessary headers, formatting, and references, producing a comprehensive and coherent supply chain optimization report. This meticulous approach ensures the report is data-driven, actionable, and presented professionally.

Step 5: Final Report Generation

By seamlessly integrating data acquisition, automated EDA, embedding generation, query execution with LLM, report generation, and parsing, ZBrain delivers the final supply chain optimization report, empowering organizations with actionable insights, timely suggestions and strategic decision-making capabilities.

Result

Optimized Supply Chain Management

By harnessing an automated, AI-driven approach, ZBrain remarkably reduces the time and resources required for supply chain optimization within the consumer electronics industry. Previously, the conventional optimization process, often taking up to 32 hours, is now streamlined to a mere 3 hours, leading to significant time and cost efficiencies. Supply chain managers can expedite decision-making processes, leading to enhanced strategic planning and a strengthened supply chain foundation tailored to the unique demands of the consumer electronics sector. Moreover, ZBrain enables proactive identification and mitigation of potential bottlenecks and risks, fostering resilience and agility within the supply chain network. Embrace ZBrain to unlock unparalleled operational efficiency and propel your organization toward sustained growth and success in the dynamic consumer electronics market.

Example Report

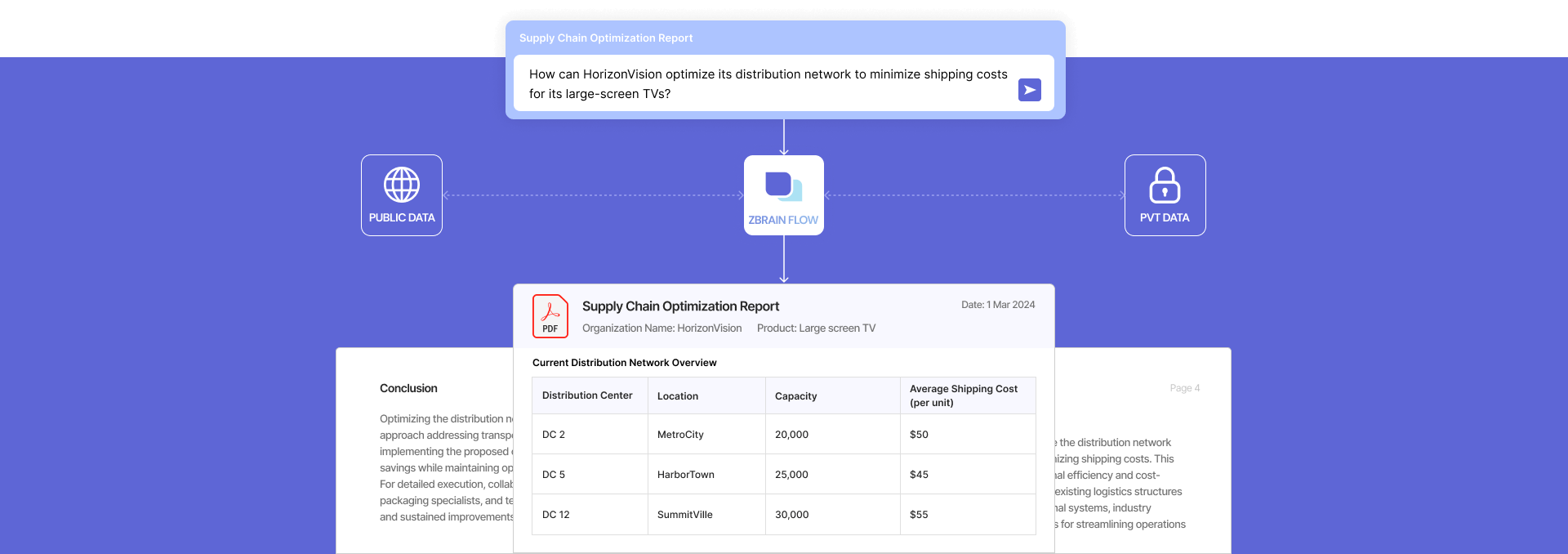

Prompt:

How can HorizonVision optimize its distribution network to minimize shipping costs for its large-screen TVs?

Executive Summary

The objective of this supply chain optimization report is to assess and refine the distribution network supporting HorizonVision’s large-screen TVs, with a specific focus on minimizing shipping costs. This optimization initiative is paramount due to its potential to enhance operational efficiency and cost-effectiveness within the supply chain significantly. By thoroughly analyzing existing logistics structures and processes and incorporating data from various sources, including internal systems, industry benchmarks, and logistics partners, the report aims to identify opportunities for streamlining operations and reducing shipping expenses.

1. Current Distribution Network Overview

|

Distribution Center

|

Location

|

Capacity

|

Average Shipping Cost (per unit)

|

|---|---|---|---|

| DC 2 | MetroCity | 20,000 | $50 |

| DC 5 | HarborTown | 25,000 | $45 |

| DC 12 | SummitVille | 30,000 | $55 |

2. Shipping Cost Breakdown (per unit)

|

Component

|

Cost Breakdown (%)

|

|---|---|

| Transportation | 60 |

| Packaging | 20 |

| Handling and Processing | 15 |

| Miscellaneous | 5 |

3. Proposed Optimization Strategies

a. Transportation Optimization:

-

Route Optimization: Utilize advanced route planning algorithms to identify the most cost-effective shipping routes and carriers, considering factors such as distance, traffic patterns, and fuel costs.

-

Consolidation: Explore opportunities to consolidate shipments to minimize transportation costs by combining multiple smaller orders into larger shipments.

-

Mode Selection: Evaluate different transportation modes (e.g., trucking, rail) to determine the most efficient and cost-effective option for transporting large-screen TVs.

b. Packaging Efficiency

-

Packaging Redesign: Collaborate with packaging experts to redesign packaging for large-screen TVs to optimize space utilization, reduce packaging material costs, and minimize the shipping volume.

-

Eco-friendly Materials: Consider using eco-friendly packaging materials that are both cost-effective and sustainable to reduce environmental impact and lower packaging costs.

c. Handling and Processing Optimization

-

Automation Implementation: Invest in automation technologies such as conveyor systems for order processing and handling to increase efficiency, reduce labor costs, and minimize errors.

-

Optimized Warehousing: Implement smart warehousing solutions with automated storage and retrieval systems to improve inventory management, streamline order picking, and reduce handling time.

d. Miscellaneous Cost Reduction

-

Energy Efficiency: Evaluate energy consumption in distribution centers and implement energy-efficient solutions such as LED lighting and HVAC system upgrades to reduce operational costs.

-

Technology Adoption: Integrate advanced technologies such as IoT sensors and real-time tracking systems to monitor shipments, optimize routing, and improve overall supply chain visibility and efficiency.

4. Expected Cost Savings

Implementing the proposed optimization strategies is expected to result in a significant reduction in shipping costs, potentially achieving cost savings of up to 20% based on preliminary analysis.

5. Implementation Plan

-

Phase 1 (0-3 months): Conduct detailed analysis and planning for route optimization, consolidation, and packaging redesign initiatives.

-

Phase 2 (3-6 months): Implement automation technologies for order processing, handling, and warehousing optimization.

-

Phase 3 (6-12 months): Monitor and evaluate the effectiveness of implemented strategies, make necessary adjustments, and continue to identify opportunities for further optimization.

Conclusion

Optimizing the distribution network for HorizonVision large-screen TVs requires a comprehensive approach addressing transportation, packaging, handling, and miscellaneous costs. By strategically implementing the proposed optimization strategies, the supply chain can achieve substantial cost savings while maintaining operational efficiency and improving customer satisfaction.

For detailed execution, collaboration with relevant stakeholders, including logistics experts, packaging specialists, and technology providers, is essential to ensure successful implementation and sustained improvements.